Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Power plant slag is a common industrial waste that is often considered useless waste. However, through processing and reuse, these wastes can be turned into useful materials and even create new commercial value. In this article, we will explore the methods and steps for the processing and reuse of power plant slag.

1. Types of slag

Power plant slag is mainly divided into two types: coarse slag and fine slag. Coarse slag refers to large pieces of slag, usually used for landfill or as road construction materials. Fine slag refers to smaller slag that can be used for the production of building materials such as concrete, cement, bricks, etc.

2. Slag processing

2. Slag processing

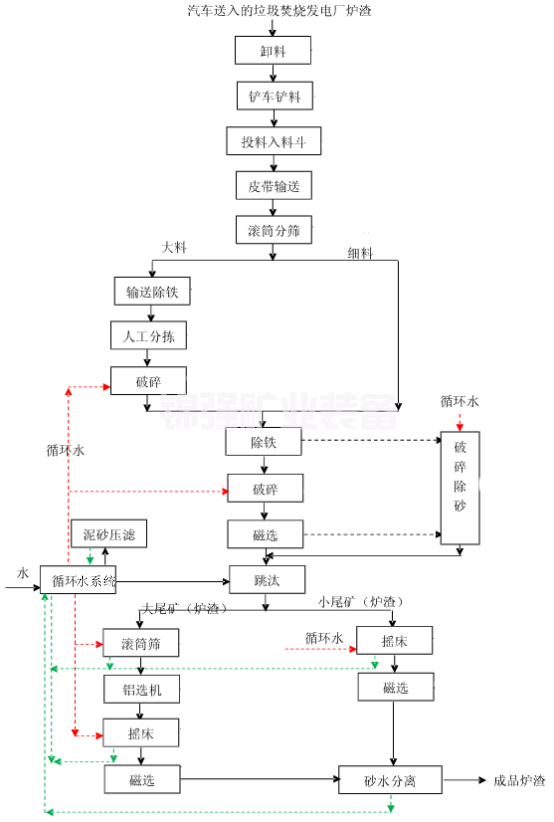

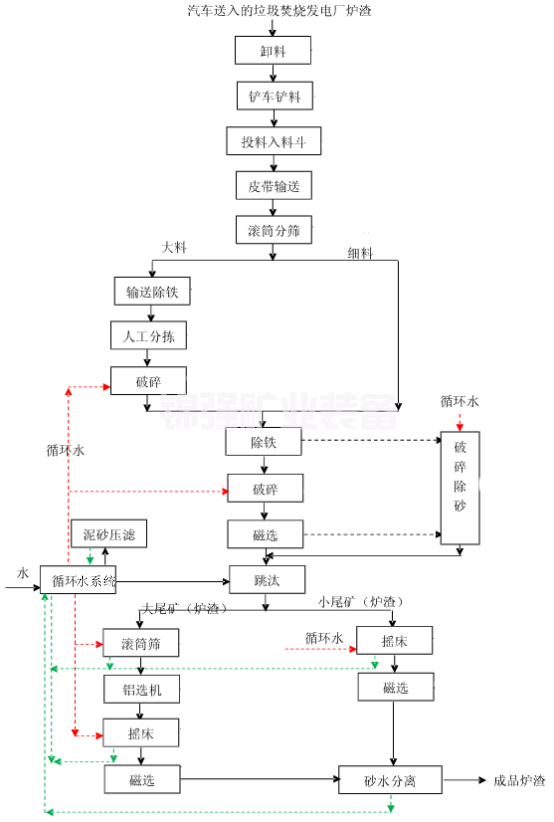

Slag processing is the process of converting slag into useful materials. This process usually includes steps such as crushing, screening, grinding, and sintering. Among them, crushing and screening are the most basic steps, which can separate the slag into different particle sizes. Grinding and sintering can convert slag into finer powder and hard bricks.

3. Slag reuse

After slag processing, it can be reused in different fields. The following are some common methods of slag reuse:

(1) Concrete production

Slag can be used for concrete production and can replace some of the cement used. This can reduce the cost of concrete and reduce environmental pollution.

(2) Cement production

Slag can be used for cement production and can replace some of the raw materials used. This can reduce the cost of cement and reduce environmental pollution.

(3) Brick production

Slag can be used for brick production and can replace the use of some clay. This can reduce the cost of bricks and reduce environmental pollution.

(4) Road construction

Slag can be used for road construction and can replace a portion of crushed stone. This can reduce the cost of road construction and reduce environmental pollution.

4. Advantages of slag processing and reuse

4. Advantages of slag processing and reuse

The processing and reuse of  slag has the following advantages:

slag has the following advantages:

(1) Reduce environmental pollution caused by waste

The reuse of slag processing can reduce the pollution of waste to the environment. This can protect the environment and reduce the consumption of natural resources.

(2) Reduce production costs

The reuse of slag processing can reduce production costs. This can improve the competitiveness of enterprises and increase their profits.

(3) Creating New Business Value

(3) Creating New Business Value

The processing and reuse of slag can create new commercial value. This can promote economic development and increase employment opportunities.

5. Conclusion

The processing and reuse of power plant slag is a beneficial work. By processing and reusing slag, environmental pollution caused by waste can be reduced, production costs can be reduced, and new commercial value can be created. We should actively promote the methods of slag processing and reuse, protect the environment, and promote economic development.

Power plant slag processing and reuse

Power plant slag processing and reuseRelated Information