Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

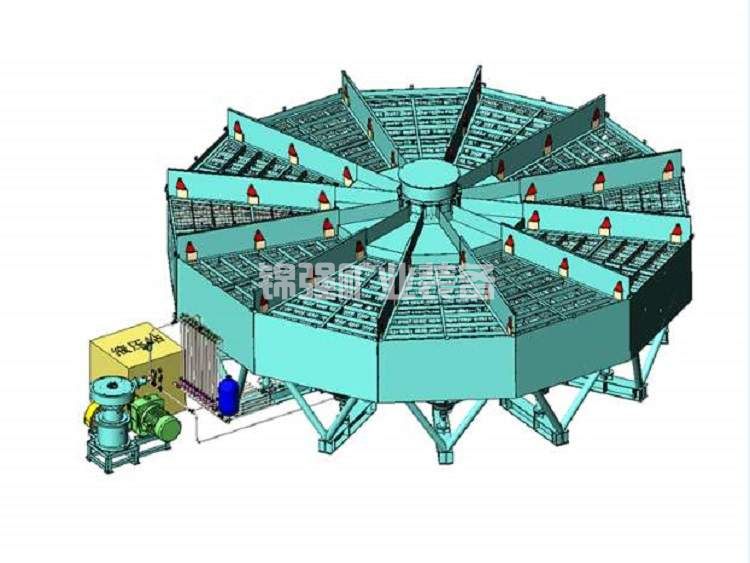

Tin tungsten sand gravity separation equipment is a specialized beneficiation equipment for tin tungsten ores. It can re select the original ore, improve the quality and recovery rate of tin tungsten sand, thereby improving resource utilization and economic benefits. This article will introduce the operating steps and precautions of the tin tungsten sand gravity separation equipment to help you better use this equipment.

1、 Operating Steps of Tin Tungsten Sand Gravity Separation Equipment

1. Preparation work

Before using the tin tungsten sand gravity separation equipment, some preparation work needs to be done. Firstly, it is necessary to inspect the equipment to ensure its normal operation. Secondly, it is necessary to prepare ore and water. The ore needs to be crushed and screened to remove impurities and fine powder. Water needs to be treated to ensure its cleanliness.

2. Adjust equipment parameters

Before performing reselection, it is necessary to adjust the parameters of the equipment. This mainly includes adjusting the angle of the inclined plate, adjusting the vibration frequency and amplitude, and adjusting the feed concentration. The adjustment of these parameters needs to be based on specific circumstances to achieve the best beneficiation effect.

3. Perform reselection

3. Perform reselection

When conducting gravity separation, it is necessary to evenly distribute the ore on the surface of the equipment and separate the ore through the impact of water. During the re selection process, it is necessary to continuously adjust equipment parameters to ensure the beneficiation effect. At the same time, it is necessary to promptly clean the impurities and fine powder inside the equipment to avoid affecting the re selection effect.

4. Collect tin tungsten sand

After the re selection is completed, the collected tin tungsten sand needs to be graded and dried. Grading can be based on particle size for better application in different industrial fields. Drying can be done by natural air drying or mechanical drying.

2、 Precautions for Tin Tungsten Sand Gravity Separation Equipment

1. Safe operation

When using tin tungsten sand gravity separation equipment, it is necessary to pay attention to safe operation. Firstly, wear protective glasses and gloves to prevent ore from splashing into the eyes or skin. Secondly, it is necessary to maintain cleanliness and tidiness around the equipment to avoid accidents.

2. Equipment maintenance

The tin tungsten sand gravity separation equipment needs regular maintenance to ensure its normal operation. Mainly including cleaning impurities and fine powder inside the equipment, replacing equipment components, etc. When maintaining equipment, it is necessary to turn off the power supply and take corresponding safety measures.

3. Fine management

3. Fine management

The  tin tungsten sand gravity separation equipment needs to be carefully managed to improve beneficiation efficiency and economic benefits. This mainly includes classifying ores, adjusting equipment parameters, and monitoring equipment operation. These management measures can effectively improve the quality and recovery rate of tin tungsten sand, thereby reducing production costs and environmental pollution.

tin tungsten sand gravity separation equipment needs to be carefully managed to improve beneficiation efficiency and economic benefits. This mainly includes classifying ores, adjusting equipment parameters, and monitoring equipment operation. These management measures can effectively improve the quality and recovery rate of tin tungsten sand, thereby reducing production costs and environmental pollution.

Summary:

Tin tungsten sand gravity separation equipment is an important mineral processing equipment that can effectively improve the quality and recovery rate of tin tungsten sand. When using tin tungsten sand gravity separation equipment, it is necessary to pay attention to safe operation, equipment maintenance, and fine management to ensure the normal operation of the equipment and the beneficiation effect. At the same time, it is necessary to adjust equipment parameters and classify ores according to specific circumstances to achieve the best beneficiation effect.

Tin tungsten sand gravity separation equipment

Tin tungsten sand gravity separation equipmentRelated Information