Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Sand tin is an important mineral resource widely used in fields such as metallurgy, mechanical manufacturing, and electronics. The mining and beneficiation process of sand tin has always been the focus of attention for mining workers. At present, the sand tin gravity beneficiation process has become one of the main methods for sand tin beneficiation. This article will introduce the process flow and operating steps of sand tin gravity beneficiation.

1、 Sand tin gravity beneficiation process flow

The sand tin gravity beneficiation process utilizes the different settling velocities of minerals in the gravity field for separation. The process mainly includes steps such as crushing, grinding, grading, gravity separation, and selection.

1. Crushing

After the sand tin ore is blasted in the mine, it needs to be crushed. The purpose of crushing is to reduce the particle size of the ore and prepare for subsequent grinding and grading processes.

2. Grinding

The crushed sand tin ore needs to be ground. The purpose of grinding is to refine the ore, improve its leaching rate and selectivity. Grinding equipment includes ball mills, short column mills, etc.

3. Grading

The sand tin ore after grinding needs to be graded. The purpose of grading is to classify ores according to their particle size, in preparation for subsequent gravity and selection processes. Commonly used grading equipment includes spiral classifiers, screening machines, etc.

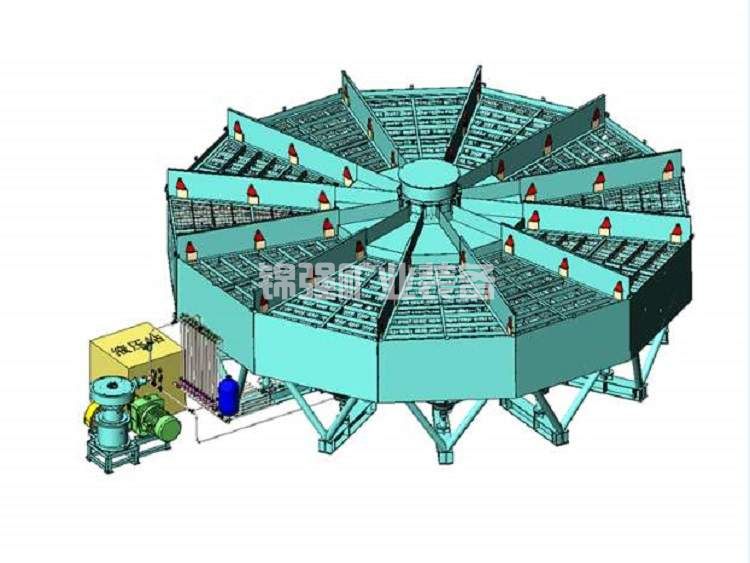

4. Reselection

The graded sand tin ore needs to undergo gravity separation treatment. The purpose of gravity separation is to separate useful minerals from useless minerals by using the gravity Separation principle. Commonly used gravity separation equipment includes heavy medium concentrators, centrifugal concentrators, etc.

5. Selection

The sand tin ore after re selection needs to be carefully treated. The purpose of selection is to further improve the grade and recovery rate of useful minerals in the ore. Commonly used selection equipment includes vibration table, inclined plate flotation machine, etc.

2、 Operation steps of sand tin gravity beneficiation process

1. Crushing operation

(1) Before the ore enters the crusher, it should be screened to separate the large pieces of ore.

(2) Adjust the discharge port of the crusher to ensure that the discharge particle size meets the requirements.

2. Grinding operation

(1) Select appropriate grinding equipment and media based on the hardness and grinding requirements of the ore.

(2) Adjust the inlet and outlet of the grinding machine to ensure uniform feeding and discharging.

3. Grading operations

3. Grading operations

(1) Select appropriate grading equipment based on the particle size of the ore.

(2) Adjust the inlet and outlet of the grading equipment to ensure uniform feeding and discharging.

4. Reselection operation

(1) Appropriate gravity concentration equipment shall be selected according to the density difference between useful minerals and useless minerals in ores.

(2) Adjust the inlet and outlet of the re selection equipment and the density of the medium to achieve the best separation effect.

5. Selection operation

(1) Select appropriate selection equipment based on the difference in buoyancy between useful and useless minerals in the ore.

(2) Adjust the inlet and outlet of the selected equipment and the water level to achieve the best separation effect.

3、 Conclusion

The  sand tin gravity beneficiation process is an effective method for ore separation. The process flow includes steps such as crushing, grinding, grading, gravity separation, and selection. During the operation process, it is necessary to select appropriate equipment and adjust equipment parameters based on the characteristics and process requirements of the ore to achieve the best separation effect.

sand tin gravity beneficiation process is an effective method for ore separation. The process flow includes steps such as crushing, grinding, grading, gravity separation, and selection. During the operation process, it is necessary to select appropriate equipment and adjust equipment parameters based on the characteristics and process requirements of the ore to achieve the best separation effect.

Sand tin gravity beneficiation process flow

Sand tin gravity beneficiation process flowRelated Information