Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Tin tungsten ore is an important metal ore mainly used for manufacturing high-tech products such as tungsten steel and hard alloys. Gravity beneficiation technology is a commonly used beneficiation method in the mining and processing of tin tungsten ore. This article will introduce the principle, operating steps, and application of gravity beneficiation technology for tin tungsten ore.

1、 The principle of gravity beneficiation technology for tin tungsten ore

The gravity beneficiation technology of tin tungsten ore is a beneficiation method that utilizes differences in mineral particle size, density, and specific gravity for separation. Under the action of gravity field, mineral particles settle and float in the water flow according to their density and specific gravity, thus achieving the separation of minerals.

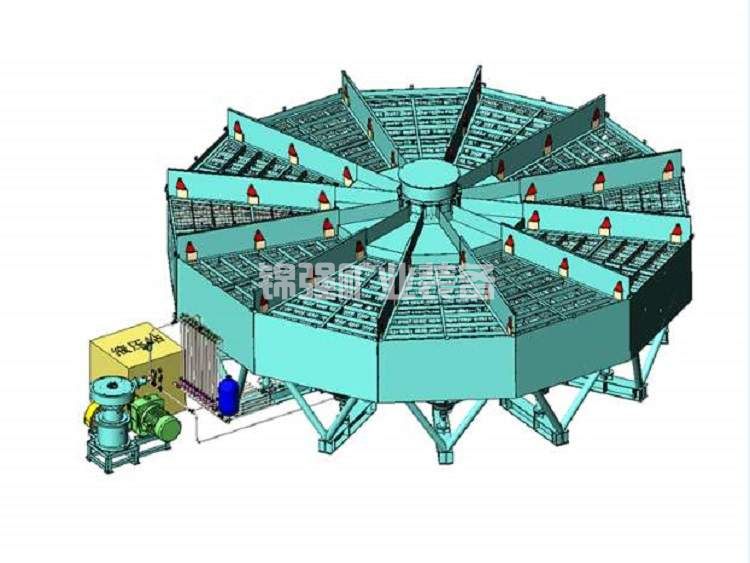

The gravity beneficiation technology of tin tungsten ore mainly includes several stages such as heavy medium separation, gravity flotation, and gravity beneficiation. Among them, heavy medium separation is the separation of ore in heavy medium to achieve the purpose of preliminary separation; Gravity flotation utilizes the power of water flow and air to separate minerals from waste rocks; Gravity beneficiation is the use of gravity field to separate minerals and achieve the ultimate goal of beneficiation.

2、 Operation steps of gravity beneficiation technology for tin tungsten ore

1. Crushing and screening of ores

1. Crushing and screening of ores

Firstly, the tin tungsten ore is crushed and screened to obtain mineral particles suitable for gravity beneficiation.

2. Heavy medium sorting

The ore is put into the heavy medium, and the mineral is separated by the density difference of the heavy medium.

3. Gravity flotation

The minerals sorted by heavy media are put into a gravity flotation cell, and the minerals are separated from the waste rock using the force of water flow and air.

4. Gravity beneficiation

4. Gravity beneficiation

Put the minerals that have undergone gravity flotation into a gravity concentrator, and use the effect of gravity field to separate the minerals to achieve the final beneficiation purpose.

5. Mineral dust collection and tailings treatment

During the beneficiation process, a large amount of tailings and dust will be generated. It is necessary to treat tailings and recycle useful minerals from them. At the same time, collect and treat the generated dust to reduce its impact on the environment.

3、 Application of gravity beneficiation technology for tin tungsten ore

The gravity beneficiation technology of tin tungsten ore is widely used in the mining and processing process of tin tungsten ore. This technology has the advantages of high efficiency, low cost, and wide applicability, and is widely used in the beneficiation process of tin tungsten ore. At the same time, with the continuous progress of technology, the gravity beneficiation technology of tin tungsten ore is also constantly innovating and developing, providing strong support for the mining and processing of tin tungsten ore.

Conclusion

Conclusion

The gravity beneficiation technology of tin tungsten ore is a commonly used beneficiation method, which utilizes differences in mineral particle size, density, and specific gravity for separation. In the beneficiation process, it is necessary to carry out operational steps such as ore crushing and screening, heavy medium separation, gravity flotation, and gravity beneficiation. The gravity beneficiation technology of tin tungsten ore has the advantages of high efficiency, low cost, and wide applicability, and is widely used in the mining and processing process of tin tungsten ore.

Gravity beneficiation technology for tin tungsten ore

Gravity beneficiation technology for tin tungsten oreRelated Information